Is your Ford tractor refusing to roar to life? A sputtering start, a click, or dead silence can be incredibly frustrating, especially when you've got work to do. Often, the culprit behind these starting issues lies in the starter solenoid wiring. This seemingly small component plays a crucial role in cranking your engine, and understanding its function and proper wiring is key to keeping your tractor running reliably.

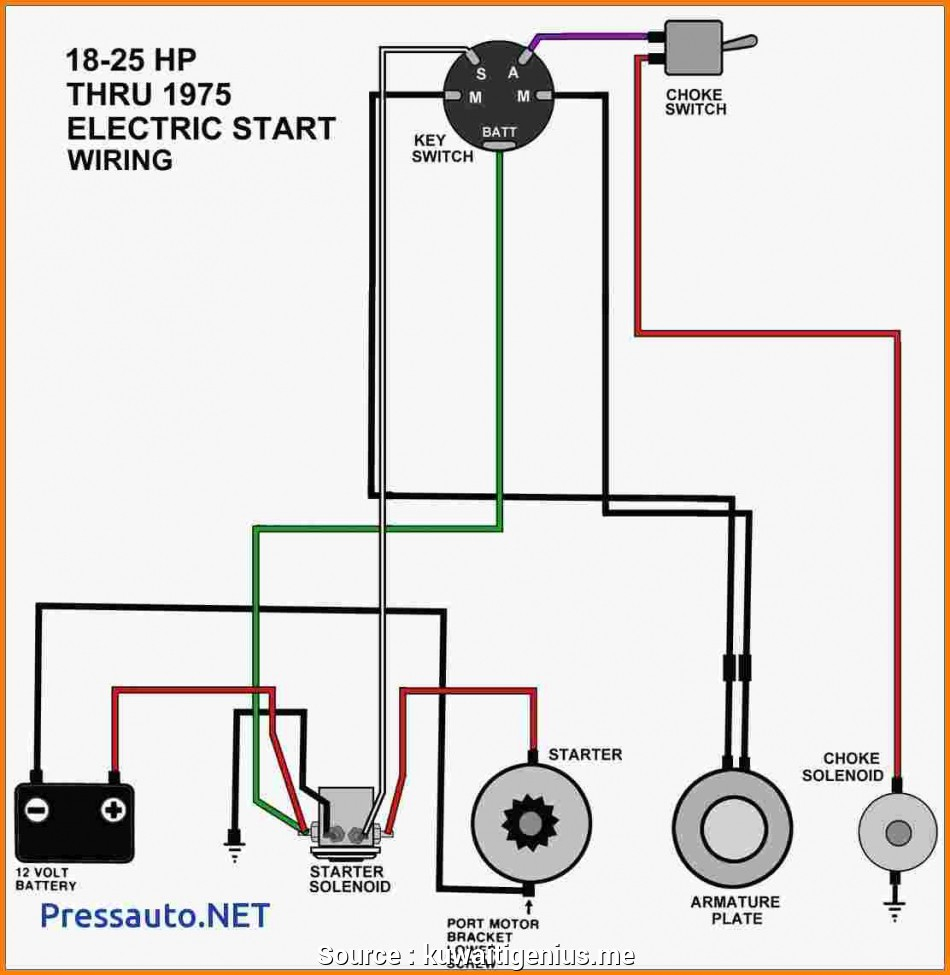

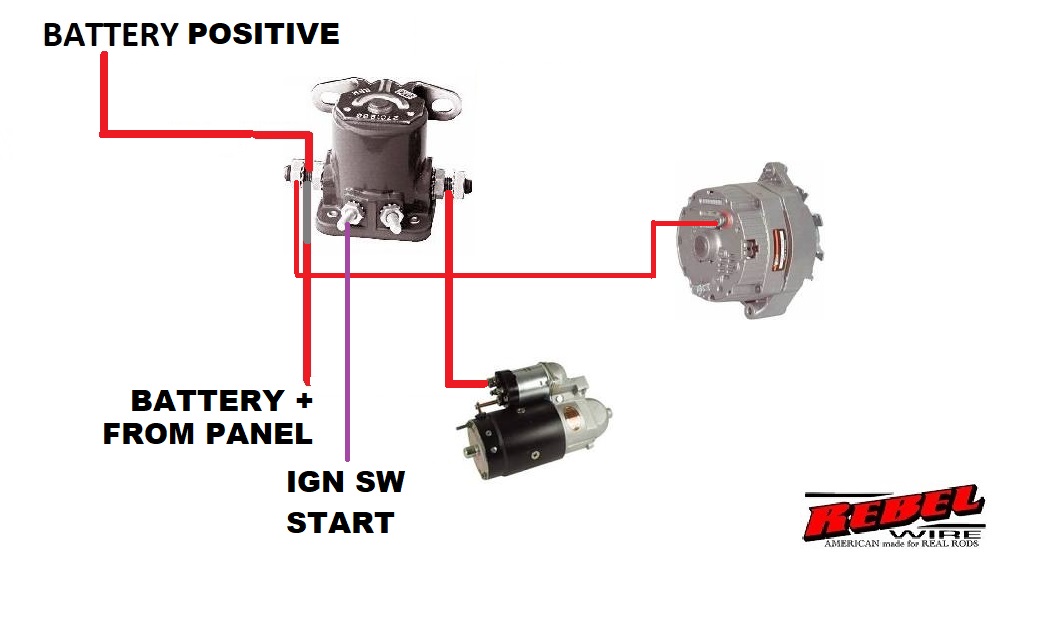

The starter solenoid acts as a heavy-duty relay, controlled by the ignition switch. When you turn the key, a small current flows through the ignition switch to the solenoid. This energizes the solenoid, closing a high-current circuit that sends power directly to the starter motor, cranking the engine. Without a properly functioning solenoid and correctly configured wiring, your tractor is going nowhere fast.

The use of starter solenoids in Ford tractors dates back decades, evolving alongside advancements in electrical systems. Early tractors relied on simpler setups, while modern models often incorporate safety features and more complex wiring schemes. Regardless of the age of your tractor, the underlying principle remains the same: deliver a powerful jolt of electricity to the starter motor when you turn the key. This seemingly simple process can be complicated by corrosion, loose connections, or faulty components within the Ford tractor starter solenoid wiring system.

Understanding the wiring diagram for your specific Ford tractor model is essential for diagnosing and resolving starting problems. These diagrams, often found in the operator's manual or online resources, illustrate the connections between the battery, ignition switch, solenoid, and starter motor. Familiarizing yourself with these connections will empower you to troubleshoot effectively and pinpoint the source of any starting woes.

Ignoring a faulty Ford tractor starter solenoid wiring setup can lead to more than just inconvenience. Repeatedly attempting to start a tractor with a wiring problem can damage the starter motor, battery, and other electrical components, leading to costly repairs down the road. Taking the time to understand and address any wiring issues will save you money and keep your tractor running smoothly for years to come.

One benefit of understanding the Ford tractor starter solenoid wiring is the ability to diagnose and fix problems yourself, saving money on mechanic fees. For example, a loose connection can be easily tightened, and a corroded wire can be cleaned or replaced at minimal cost.

Another advantage is increased reliability. By regularly inspecting and maintaining the wiring, you can prevent unexpected breakdowns and ensure your tractor is ready to work when you need it. Imagine the frustration of a stalled tractor in the middle of a critical task – proper wiring maintenance avoids such scenarios.

Finally, knowing the intricacies of your tractor’s electrical system empowers you to perform upgrades or modifications with confidence. Adding accessories, like work lights or a winch, requires a solid understanding of the existing wiring and the ability to integrate new components safely.

Advantages and Disadvantages of Understanding Ford Tractor Starter Solenoid Wiring

| Advantages | Disadvantages |

|---|---|

| Cost savings on repairs | Requires time and effort to learn |

| Increased tractor reliability | Potential for incorrect diagnosis and further damage if not careful |

| Ability to perform upgrades/modifications | Requires specific tools and resources (e.g., multimeter, wiring diagrams) |

Troubleshooting Ford Tractor Starter Solenoid Wiring Problems:

1. Check the battery voltage: A weak battery can cause starting issues, even with proper wiring.

2. Inspect the solenoid connections: Look for loose or corroded wires and terminals.

3. Test the solenoid: Use a multimeter to check for continuity and voltage.

4. Examine the starter motor: Ensure the connections are secure and the motor is functioning correctly.

5. Trace the wiring: Follow the wiring diagram to identify any breaks or shorts in the circuit.

Frequently Asked Questions:

1. What is a starter solenoid? A: It's a heavy-duty relay that controls the starter motor.

2. Where is the solenoid located? A: Typically near the starter motor or on the firewall.

3. How do I test a solenoid? A: Use a multimeter to check for continuity and voltage.

4. What are common solenoid wiring problems? A: Loose connections, corroded wires, and faulty solenoids.

5. Can I replace a solenoid myself? A: Yes, with basic tools and knowledge.

6. What gauge wire should I use for the solenoid? A: Consult your tractor's wiring diagram.

7. How do I prevent solenoid wiring problems? A: Regular inspection and cleaning of connections.

8. Where can I find a wiring diagram for my Ford tractor? A: In the operator's manual or online resources.

Mastering the intricacies of your Ford tractor's starter solenoid wiring is an investment in both time and money. While it may require some initial effort to understand the various components and their interactions, the long-term benefits far outweigh the initial learning curve. A well-maintained electrical system ensures reliable starts, reduces the risk of unexpected breakdowns, and empowers you to tackle maintenance and upgrades with confidence. By taking the time to learn about this critical system, you are not just fixing a potential problem but also building a deeper understanding of your tractor and taking control of its long-term health. This knowledge translates to fewer trips to the mechanic, more time spent productively using your tractor, and the satisfaction of knowing you can handle whatever challenges come your way. So, grab your tools, consult your wiring diagram, and embark on the journey to becoming a Ford tractor electrical system guru. Your wallet and your peace of mind will thank you.

Decoding medicare part g coverage your guide

Behr blue bedroom bliss your guide to perfect paint

Decoding the es pay scale in virginia your guide to va salaries