Imagine this: you turn the key in your trusty Ford tractor, expecting the familiar rumble of the engine, but are met with silence. The culprit? Possibly a faulty Ford tractor starter solenoid. This often-overlooked component plays a critical role in starting your tractor's engine. Understanding its function, potential problems, and maintenance can save you time, money, and frustration.

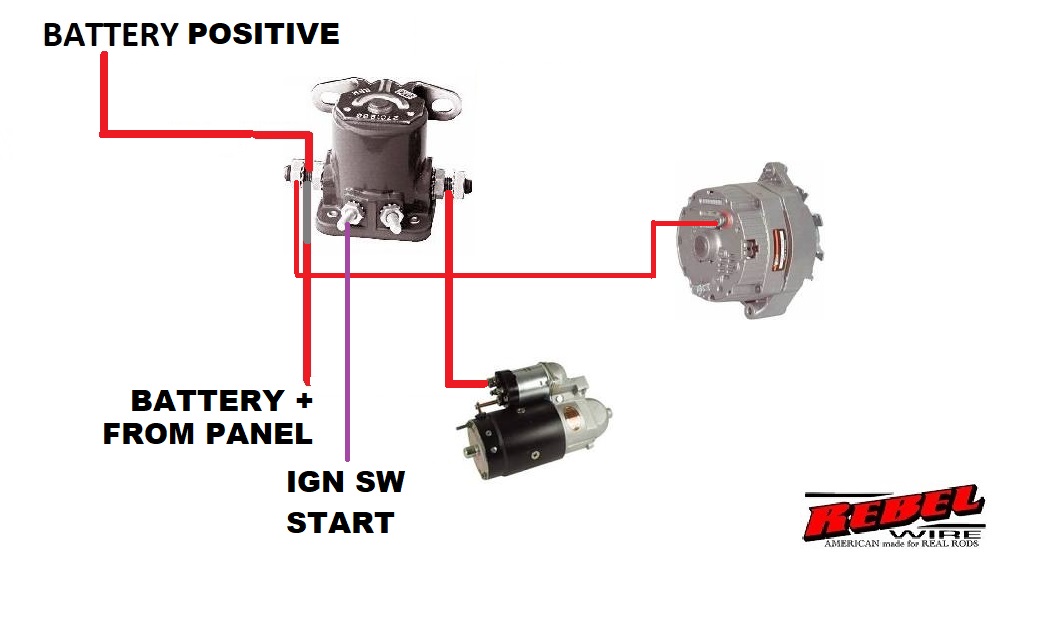

The Ford tractor starter solenoid acts as an electrical relay between the battery and the starter motor. When you turn the key, the solenoid engages, closing a high-current circuit that sends power from the battery to the starter. This surge of electricity spins the starter motor, cranking the engine to life. Without a functioning solenoid, your Ford tractor remains stubbornly silent.

Early Ford tractors relied on simpler starting mechanisms. However, as engines became larger and more powerful, the demand for a more robust starting system grew. The starter solenoid emerged as a solution, allowing for a smaller ignition switch to control the high current needed to engage the starter. This evolution marked a significant improvement in the starting reliability of Ford tractors.

The importance of the Ford tractor starter solenoid cannot be overstated. It is the vital link that connects the battery's power to the starter motor, ensuring the engine can be cranked effectively. A malfunctioning solenoid can lead to a variety of issues, from intermittent starting problems to a complete inability to start the tractor. This can disrupt workflow and lead to costly downtime, especially during crucial farming seasons.

Several issues can plague a Ford tractor starter solenoid. A common problem is corrosion on the solenoid terminals, preventing the flow of electricity. A clicking sound when you turn the key often indicates a failing solenoid, suggesting it's not effectively engaging the starter motor. Other issues include a burnt-out solenoid coil or a stuck plunger, both of which prevent the solenoid from functioning correctly.

Testing the Ford tractor starter solenoid is relatively straightforward. One method involves using a multimeter to check for voltage at the solenoid terminals. Another method involves bypassing the solenoid with a screwdriver to see if the starter motor engages. These tests can help pinpoint whether the solenoid is the source of the starting problem.

Replacing a Ford tractor starter solenoid is generally a simple task, requiring basic hand tools. Disconnecting the battery cables is crucial for safety. Once the old solenoid is removed, the new one can be installed, ensuring proper connection of the wires and terminals. After installation, testing the starting system is essential to confirm the new solenoid is functioning correctly.

Maintaining your Ford tractor’s starting system, including the solenoid, can prevent future problems. Regularly cleaning the solenoid terminals and ensuring tight connections can significantly extend its lifespan. Inspecting the wiring for damage and addressing any issues promptly can further improve the reliability of the starting system.

Advantages and Disadvantages of Ford Tractor Starter Solenoids

| Advantages | Disadvantages |

|---|---|

| Enables reliable engine starting | Subject to corrosion and wear |

| Relatively inexpensive to replace | Can fail suddenly, causing downtime |

| Easy to install and troubleshoot | Requires periodic inspection and maintenance |

Five best practices: 1. Keep terminals clean. 2. Inspect wiring regularly. 3. Test periodically with a multimeter. 4. Replace at first sign of consistent issues. 5. Use quality replacement parts.

FAQs:

1. Why is my Ford tractor clicking when I turn the key? A clicking sound usually indicates a failing solenoid or weak battery.

2. How do I test a Ford tractor starter solenoid? Use a multimeter or bypass the solenoid with a screwdriver.

3. Can I replace the solenoid myself? Yes, with basic hand tools and careful attention to safety procedures.

4. How long does a Ford tractor starter solenoid last? The lifespan varies depending on usage and maintenance, but they can last for several years.

5. What are the signs of a bad Ford tractor starter solenoid? Clicking sounds, intermittent starting, or complete failure to start.

6. How much does a Ford tractor starter solenoid cost? The price varies depending on the model and supplier, but they are generally affordable.

7. Where can I buy a Ford tractor starter solenoid? Auto parts stores, tractor dealerships, and online retailers.

8. How can I prevent Ford tractor starter solenoid problems? Regular cleaning, inspection, and prompt replacement of faulty components.

Tips and tricks: Use dielectric grease on terminals to prevent corrosion. Carry a spare solenoid for emergencies. Learn how to bypass the solenoid in case of sudden failure.

The Ford tractor starter solenoid is a small but mighty component, essential for the smooth operation of your tractor. Understanding its function, troubleshooting common problems, and implementing preventative maintenance can save you from unexpected breakdowns and ensure your Ford tractor is ready to work when you are. Regularly inspecting and cleaning the solenoid, ensuring tight connections, and addressing any wiring issues promptly can greatly extend the lifespan of the solenoid and the starting system as a whole. Don't underestimate the importance of this small component. A little preventative care can go a long way in keeping your Ford tractor running smoothly for years to come. Taking the time to familiarize yourself with the workings of your Ford tractor’s starter solenoid is a valuable investment that will pay off in increased reliability and peace of mind. By understanding the information provided here, you’ll be well-equipped to tackle any starter solenoid challenges that may arise, ensuring your Ford tractor remains a reliable workhorse for years to come.

Unlocking the warmth exploring the enchanting hues of ginger

Unlocking the secrets of the razor e300 rear axle

The absurd genius of far side cartoons