A well-maintained lawn is a source of pride for many homeowners. Behind that perfectly manicured green carpet often lies a reliable lawn tractor, a workhorse that demands proper care and understanding. A key component to keeping your tractor running smoothly is a firm grasp of its electrical system, and at the heart of that system lies the solenoid. Understanding the solenoid wiring diagram for your lawn tractor can be the difference between a quick fix and a costly repair.

The solenoid acts as an electrical switch, controlling the flow of power to vital components like the starter motor. Without a properly functioning solenoid, your tractor might refuse to start, leaving you stranded mid-mow. That's why understanding the solenoid wiring diagram is so important. It provides a visual roadmap of the electrical connections, allowing you to diagnose problems, perform maintenance, and even make upgrades with confidence.

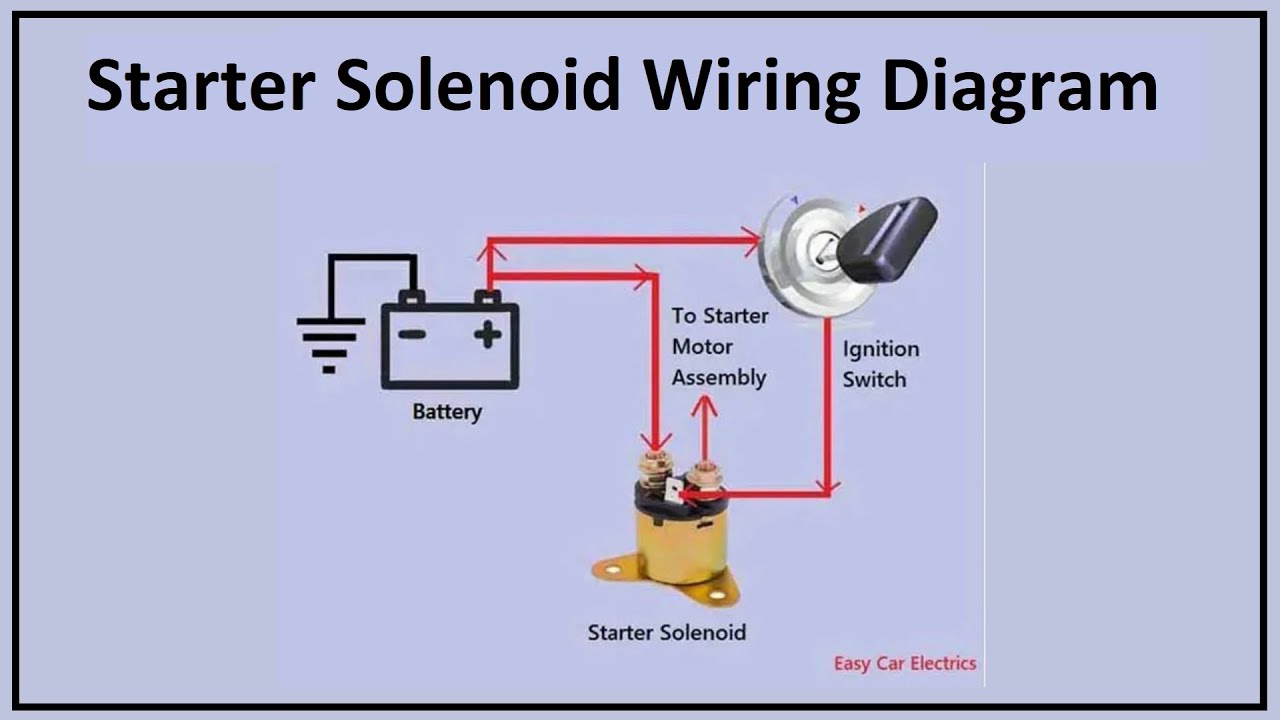

While the specific layout of a solenoid wiring diagram might vary slightly between lawn tractor models and manufacturers, the underlying principles remain consistent. Typically, the diagram depicts the solenoid itself, the battery, the ignition switch, and the starter motor, along with the wires connecting these components. Understanding the symbols and conventions used in these diagrams is crucial for accurate interpretation.

Delving into the history of solenoid wiring diagrams for lawn tractors reveals the evolution of these machines. Early tractors relied on simpler electrical systems, but as technology advanced, so did the complexity of the wiring. This underscores the importance of having access to the correct diagram for your specific model and year. You can usually find this information in the owner's manual or online resources.

One common issue related to solenoid wiring diagrams is the difficulty in locating the correct diagram for older or less common tractor models. This can pose a challenge for DIY enthusiasts who prefer to handle repairs themselves. However, online forums and communities dedicated to lawn tractors can often provide valuable assistance in sourcing these diagrams.

The solenoid receives a small electrical signal from the ignition switch when you turn the key. This small current activates the solenoid, which then closes a high-current circuit, allowing power to flow from the battery to the starter motor. The starter motor then cranks the engine, bringing it to life. A simple analogy is a light switch controlling a powerful appliance.

Benefits of understanding the solenoid wiring diagram include: 1. Easier troubleshooting: Identify electrical faults quickly. 2. Cost-effective repairs: Avoid unnecessary service calls. 3. Increased confidence: Perform maintenance tasks with assurance.

When troubleshooting, start by inspecting the wiring for any obvious damage or loose connections. Use a multimeter to test the solenoid's functionality. If the solenoid is faulty, replace it with a compatible part.

Advantages and Disadvantages of Using Solenoid Wiring Diagrams

| Advantages | Disadvantages |

|---|---|

| Simplifies Troubleshooting | Can be complex for beginners |

| Empowers DIY Repairs | Requires accurate interpretation |

| Reduces Repair Costs | May be difficult to find for older models |

Best Practices: 1. Always disconnect the battery before working on the electrical system. 2. Use the correct gauge wiring for replacements. 3. Secure all connections with appropriate connectors. 4. Consult the diagram frequently during the process. 5. If unsure, seek professional assistance.

Frequently Asked Questions: 1. Where can I find my tractor's wiring diagram? (Owner's manual, online resources) 2. How do I test a solenoid? (Multimeter) 3. What causes a solenoid to fail? (Wear and tear, electrical shorts) 4. Can I replace a solenoid myself? (Yes, with basic tools and knowledge) 5. What safety precautions should I take? (Disconnect battery) 6. How do I read the diagram symbols? (Consult a wiring diagram key) 7. What if I can't find the diagram for my model? (Online forums, manufacturer support) 8. Can I upgrade my solenoid? (Consult a professional)

Tips and tricks: Keep a copy of the wiring diagram readily available in your garage or workshop. Use a marker to highlight relevant sections for quick reference during repairs. Take clear photos of the wiring before disconnecting anything.

In conclusion, understanding the solenoid wiring diagram for your lawn tractor is a fundamental skill for any owner who wants to maintain their machine effectively and minimize downtime. From troubleshooting electrical issues to performing routine maintenance, the diagram serves as an invaluable guide. By familiarizing yourself with the symbols, connections, and best practices, you empower yourself to take control of your tractor's electrical health, saving time, money, and frustration. Investing the time to learn and understand these diagrams will undoubtedly pay off in the long run, keeping your lawn tractor running smoothly for years to come. Remember, a well-maintained tractor is a happy tractor, and a happy tractor means a beautifully manicured lawn.

Nespresso capsule deals upgrade your coffee routine for less

Mexico to canada flights your aerial adventure awaits

Decoding the electric fan switch and relay your guide to cooling control