Ever wondered how your water pump switches on and off so seamlessly? The unsung hero behind this smooth operation is often a small but mighty component: the relay. Relay connections are the backbone of many automated water pump systems, providing a safe and efficient way to control the pump's power supply. This comprehensive guide will unpack everything you need to know about relay connections for water pumps, from basic principles to advanced troubleshooting.

Controlling a water pump directly from a switch can put a significant strain on the switch contacts, especially for larger pumps. A relay acts as an intermediary, using a small current to control a much larger current flowing to the pump motor. This extends the lifespan of the switch and protects the entire system from potential electrical hazards. Think of it as a lever: a small force (the switch) controls a much larger force (the pump). This principle is fundamental to understanding the crucial role relays play in water pump automation.

The use of relays in electrical systems has a long and rich history, dating back to the early days of telegraphy. Relays were initially used to amplify weak signals over long distances. Over time, their applications expanded to various fields, including industrial control systems and automotive electronics. Their adaptation to water pump control systems was a natural progression, offering a reliable and robust solution for automated pumping operations.

The importance of a properly configured relay connection in a water pump system cannot be overstated. It ensures the longevity of the pump motor by preventing overloads and short circuits. Moreover, relays allow for automated control of the pump based on various factors, such as water level, pressure, or timing. This automation significantly enhances efficiency and convenience, particularly in applications like irrigation, water distribution, and wastewater management.

Despite their robust nature, relay connections are not immune to issues. Common problems include faulty relay contacts, loose wiring, and incorrect voltage ratings. Understanding these potential issues and implementing preventative measures is key to ensuring a reliable and efficient water pump system.

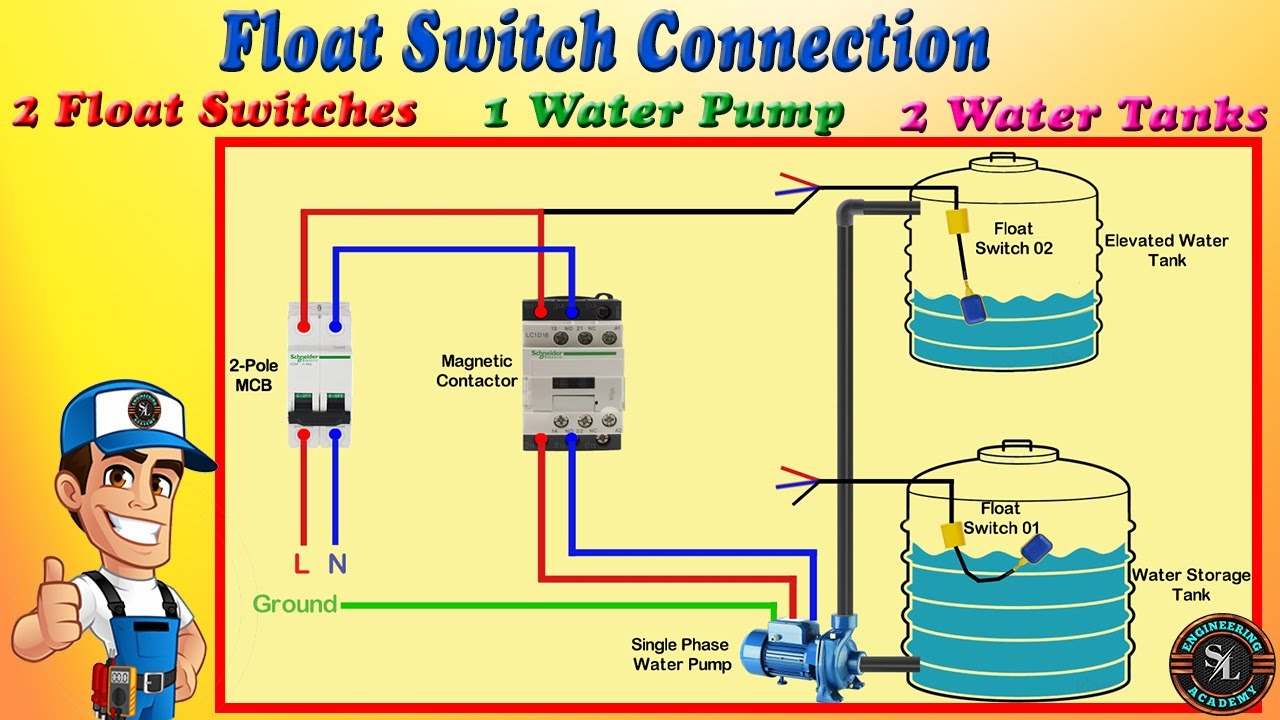

A relay is an electromagnetic switch that uses a small control current to activate a separate circuit with a higher current. In a water pump context, the control current comes from a switch, float switch, or a pressure sensor, while the higher current powers the pump motor.

For example, imagine a float switch in a water tank. As the water level drops, the float switch activates, sending a small current to the relay. The relay then closes its contacts, allowing the mains power to flow to the water pump, starting the pumping process. When the water level reaches a certain point, the float switch deactivates, cutting off the current to the relay, which in turn shuts down the pump.

Benefits of using a relay for water pump control include extended switch lifespan, automated operation, and enhanced safety through electrical isolation.

To install a relay, you need to connect the control circuit (switch/sensor) to the relay coil, and the pump motor to the relay contacts. Ensure the relay and wiring are appropriately rated for the pump's voltage and current requirements.

Advantages and Disadvantages of Relay Connections for Water Pumps

| Advantages | Disadvantages |

|---|---|

| Increased switch lifespan | Added component cost |

| Automated operation | Potential relay failure |

| Enhanced safety | Requires proper wiring and configuration |

Best practices for implementing relay connections include using appropriately sized relays, ensuring secure wiring connections, providing adequate overcurrent protection, and regularly inspecting the relay for signs of wear and tear.

Real-world examples of relay-controlled water pumps include irrigation systems, sump pumps, well pumps, and pressure booster pumps in residential and commercial buildings.

Challenges related to relay connections can include relay chattering, burnt contacts, and wiring issues. Solutions involve selecting the right relay type, ensuring proper voltage and current ratings, and implementing appropriate suppression techniques.

FAQs about relay connections include questions on wiring diagrams, troubleshooting tips, relay selection, and compatibility with different pump types.

Tips and tricks for relay connections include using a diode across the relay coil to prevent voltage spikes, using crimp connectors for secure wiring, and mounting the relay in a protected enclosure.

In conclusion, relay connections are essential for efficient and safe operation of water pumps. They provide a simple yet effective way to control the pump's power supply, extending the lifespan of the system components and enabling automation. By understanding the principles, benefits, and best practices related to relay connections, you can optimize your water pump system for reliability, performance, and longevity. Take the time to properly select and install your relay connection, and you'll reap the rewards of a smoothly running, automated water pump system for years to come. Properly implementing relay connections isn't just a good idea; it's an investment in the long-term health and efficiency of your water management system. Don't underestimate the power of this small component – it's the key to unlocking the full potential of your water pump.

Gulf coast fishing adventures family fun on the water

Starbucks gift card deals double your coffee delight

Unlocking watertowns potential jefferson county planning