There's a certain quiet confidence that comes with knowing your outboard motor is in top shape. It's the kind of assurance that allows you to focus on the horizon, the pull of the line, the glint of sunlight on the water. And at the heart of that reliable performance lies a small but crucial component: the water pump. For owners of Johnson 50 HP outboards, understanding the nuances of this cooling system cornerstone is essential.

The Johnson 50 HP outboard water pump kit isn't just a collection of parts; it's the lifeblood of your engine. This seemingly simple assembly circulates water through the engine block, preventing overheating and ensuring smooth, consistent operation. Over time, the components of this kit, including the impeller, housing, and various gaskets and seals, can wear down, leading to performance issues or even catastrophic engine failure.

Historically, outboard motors relied on basic cooling systems, but as engine technology advanced, so did the complexity of their cooling mechanisms. The Johnson 50 HP outboard, a popular choice among boating enthusiasts, incorporates a robust water pump design to meet the demands of its powerful engine. Understanding this evolution is key to appreciating the importance of regular maintenance and timely replacements of the water pump kit.

One of the most common issues related to a failing Johnson 50 HP outboard water pump is overheating. A worn impeller, a cracked housing, or a compromised seal can disrupt the flow of cooling water, causing the engine to run hotter than optimal. This can lead to decreased performance, damage to internal components, and even complete engine seizure. Regular inspection and preventative maintenance are crucial to avoid these costly and frustrating problems.

Recognizing the signs of a failing water pump is paramount. A telltale stream of water exiting the tell-tale hole is a good indicator of proper function. A weak or intermittent stream, or no stream at all, is a clear sign of a problem. Other symptoms include overheating alarms, steam from the engine, and a noticeable drop in performance. Addressing these issues promptly by replacing the water pump kit can save you time, money, and potential engine damage.

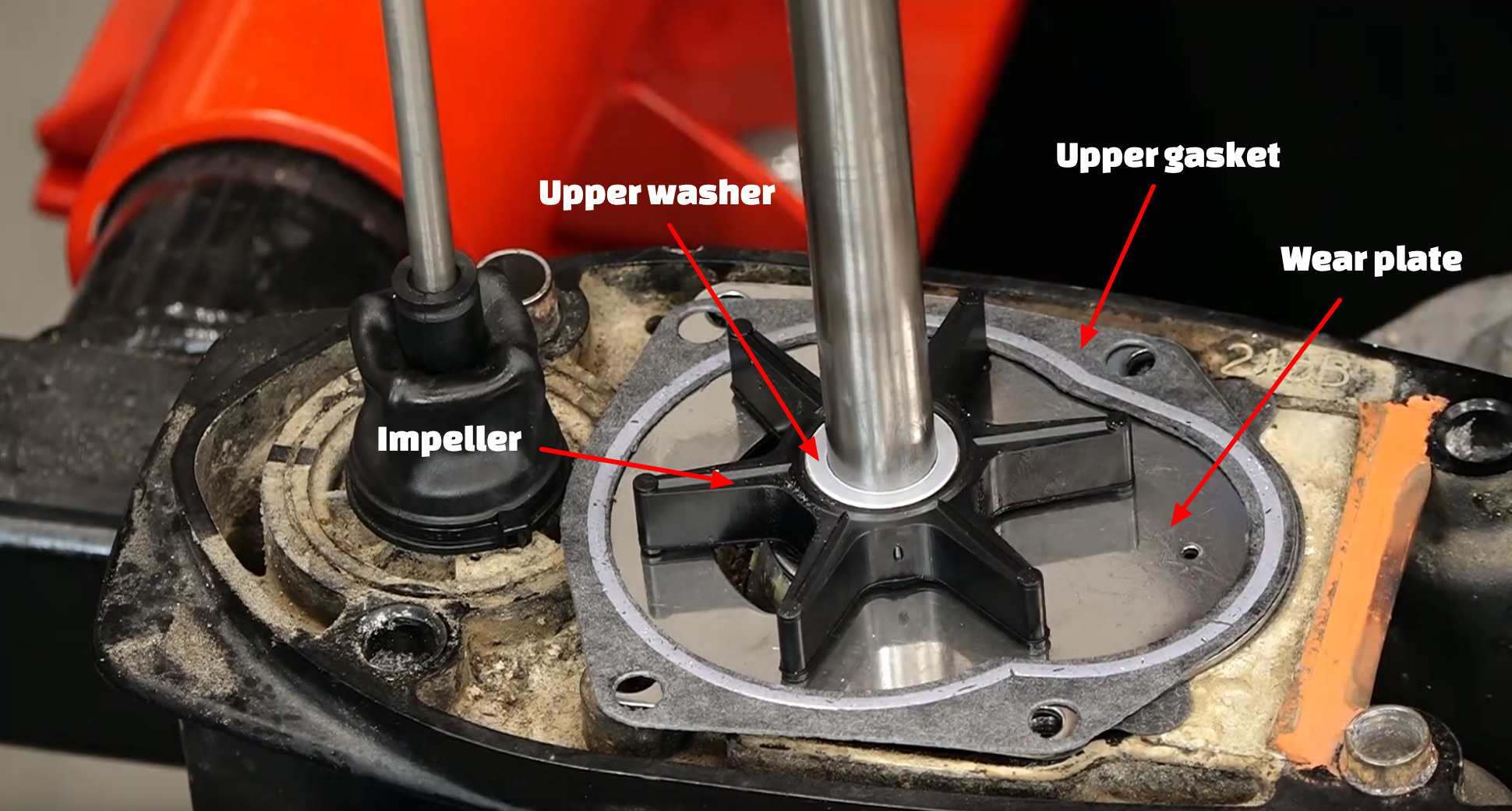

The Johnson 50 HP outboard water pump kit typically includes an impeller, housing, gaskets, seals, and other necessary hardware. The impeller is the heart of the system, a rubber component that spins and draws water into the engine. The housing contains the impeller and directs the water flow. Gaskets and seals prevent leaks and ensure proper pressure within the system. Replacing the entire kit ensures all components are fresh and working in harmony.

Three key benefits of maintaining a healthy Johnson 50 HP outboard water pump kit include optimal engine performance, extended engine life, and peace of mind on the water. A properly functioning cooling system keeps the engine running at its peak, delivering the power and reliability you expect. By preventing overheating, you protect vital internal components, extending the life of your outboard. And knowing your engine is running cool and efficiently allows you to enjoy your time on the water without worry.

Advantages and Disadvantages of DIY vs. Professional Installation

| Feature | DIY Installation | Professional Installation |

|---|---|---|

| Cost | Lower (parts only) | Higher (parts and labor) |

| Time | More time required | Less time required |

| Expertise | Requires mechanical skills | Performed by trained technicians |

Best Practice: Always use genuine Johnson parts for your water pump kit to ensure proper fit and performance.

Best Practice: Inspect the impeller regularly for wear and tear, replacing it at least annually or more often if needed.

Best Practice: Use a marine-grade lubricant on the impeller shaft during installation to prevent damage and ensure smooth operation.

Best Practice: Carefully follow the manufacturer's instructions when installing the water pump kit.

Best Practice: Flush the cooling system with fresh water after each use, especially in saltwater environments.

FAQ: What are the signs of a failing water pump? Answer: A weak or absent tell-tale stream, overheating, steam, and reduced performance.

FAQ: How often should I replace the water pump kit? Answer: At least annually or more often if needed.

In conclusion, the Johnson 50 HP outboard water pump kit is a critical component for ensuring the health and longevity of your engine. Regular maintenance, including inspection and timely replacement of the kit, is essential for optimal performance and peace of mind. By understanding the function, importance, and potential issues associated with this vital system, you can keep your Johnson 50 HP outboard running smoothly for years to come. Don't let a small part become a big problem; invest in the health of your engine and enjoy countless hours of trouble-free boating. Remember to consult your owner's manual for specific recommendations and maintenance schedules for your Johnson 50 HP outboard.

Expressing love through long poems for dad

Wichita piercing your guide to safe stylish body art

Exploring farrow ball elephants breath paint

.jpg)

.jpg)