Working on your Toyota's axle? One crucial piece of information you'll need is the correct Toyota axle nut socket size. Using the wrong size can lead to stripped nuts, damaged tools, and a whole lot of frustration. This comprehensive guide will cover everything you need to know about this seemingly small, but incredibly important, detail.

So, why is knowing the right Toyota axle nut socket size so critical? Well, imagine trying to loosen a nut with a socket that's too small. You'll likely end up rounding off the nut, making it nearly impossible to remove without specialized tools. Conversely, a socket that's too large won't grip the nut properly, potentially damaging both the nut and the socket. Finding the correct size ensures a snug fit, allowing you to apply the necessary torque without causing damage.

The specific Toyota axle nut socket size can vary depending on the model and year of your vehicle. Generally, you'll find sizes ranging from 30mm to 36mm, with 32mm and 35mm being quite common. Consulting your vehicle's repair manual is the best way to determine the exact size required for your specific Toyota. Online forums dedicated to Toyota owners can also be valuable resources for finding this information.

Historically, Toyota has used various axle nut sizes across its different models. This variation stems from differences in axle design and engineering over the years. It's crucial to avoid guessing the size. Always double-check the specifications for your particular Toyota model and year to ensure you're using the correct tool. Using the correct size isn't just about efficiency; it's about preserving the integrity of your vehicle's components.

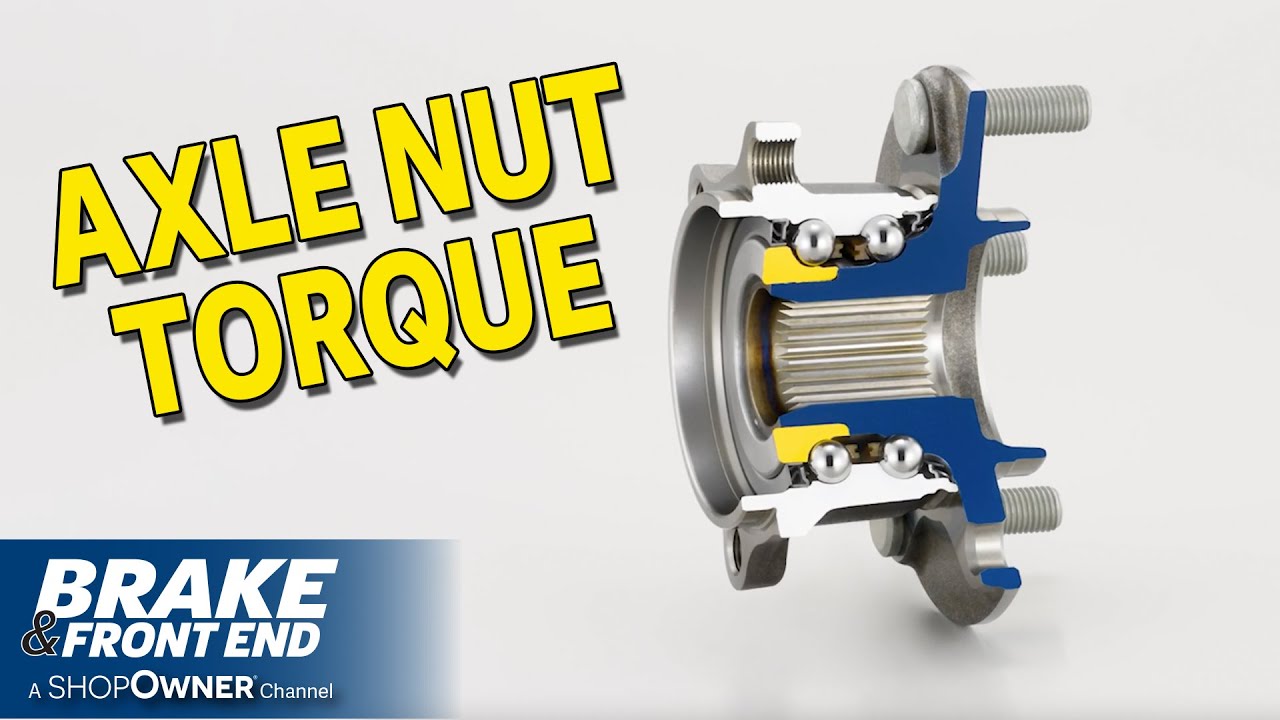

Using the correct Toyota axle nut socket size is paramount for several reasons. It prevents damage to the axle nut, ensuring its proper function in securing the axle and wheel assembly. It also protects your tools from unnecessary wear and tear. Furthermore, using the right socket size allows for the proper application of torque, crucial for maintaining the safety and stability of your vehicle.

If you’re unsure about the size, you can also measure the nut with calipers. This provides a precise measurement, helping you select the correct socket. Remember, precision is key when working with automotive components.

One common challenge is finding a deep enough socket. Axle nuts often sit recessed, requiring a deep socket for proper engagement. Ensure your chosen socket reaches the nut fully to avoid slippage and potential damage.

Another issue can arise when the axle nut is seized due to rust or corrosion. Penetrating oil can help loosen the nut before attempting removal. Patience and the correct application of force are crucial in these situations.

Advantages and Disadvantages of Using the Correct Socket Size

| Advantages | Disadvantages |

|---|---|

| Prevents damage to the axle nut | Requires knowing the correct size |

| Protects your tools | Can be challenging to find the right socket locally |

| Ensures proper torque application |

Best Practices:

1. Consult your vehicle's repair manual.

2. Use a torque wrench to ensure proper tightening.

3. Apply penetrating oil to seized nuts.

4. Use a high-quality socket for durability.

5. Double-check the size before applying force.

FAQ:

1. Where can I find the correct Toyota axle nut socket size? Check your repair manual.

2. What happens if I use the wrong size? You risk damaging the nut and your tools.

3. Can I use an impact wrench? Consult your repair manual for recommendations.

4. What if the nut is seized? Use penetrating oil.

5. What is the most common size? It varies, but 32mm and 35mm are common.

6. Do I need a special socket? A deep socket is often required.

7. Where can I buy the right socket? Auto parts stores or online retailers.

8. How much torque should I apply? Consult your vehicle's repair manual for specific torque specifications.

In conclusion, knowing the correct Toyota axle nut socket size is paramount for any DIY mechanic or professional working on these vehicles. Using the right tool ensures a smooth and efficient repair process, preventing potential damage to critical components and ensuring the long-term safety and reliability of your Toyota. By following the guidelines and tips outlined in this guide, you can confidently tackle axle-related maintenance and repairs, knowing you have the right tools for the job. Remember to always consult your vehicle's repair manual for the most accurate information and take your time to ensure a precise and safe repair. Don't underestimate the importance of this small detail; it can make all the difference in the success of your repair and the continued performance of your vehicle. Taking the time to understand and implement these best practices will save you time, money, and frustration in the long run, keeping your Toyota running smoothly for years to come. This proactive approach to maintenance is an investment in the longevity and safety of your vehicle.

Streaming the outsider exploring hbos gripping crime drama

Mastering ac system vacuuming the ultimate guide

Finding your true north decoding the feng shui house direction dilemma