Ever wondered what keeps those giant humming transformers ticking? It's not magic, it's transformer oil! This incredible fluid plays a vital role in keeping our electrical grid humming, but it needs a little TLC to stay in top shape. Ignoring transformer oil maintenance can lead to catastrophic failures, power outages, and some seriously expensive repairs. Let's dive into the electrifying world of transformer oil upkeep.

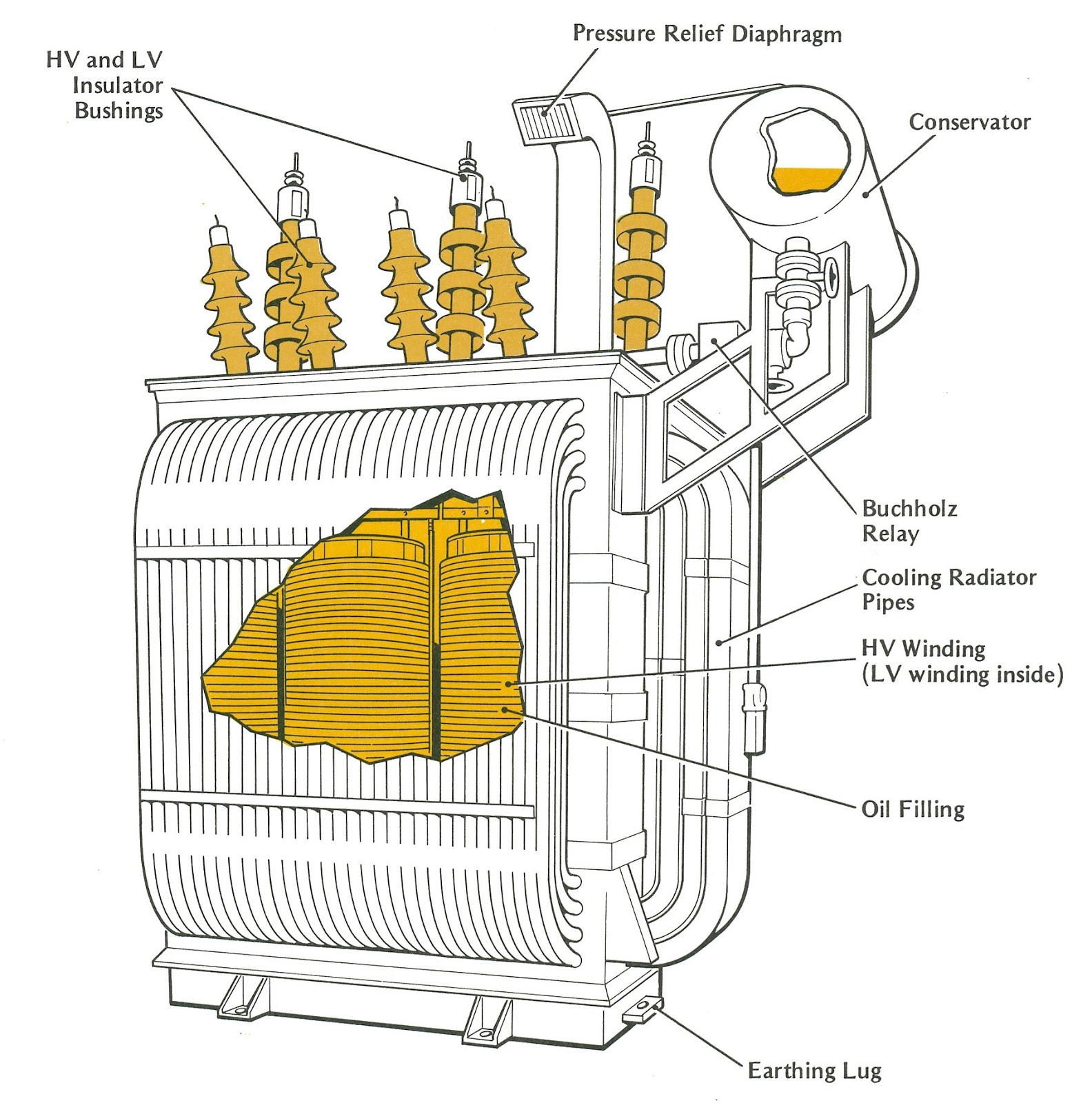

Transformer oil isn't just any oil; it's a highly refined mineral oil specifically designed to insulate and cool high-voltage transformers. It's the unsung hero of power distribution, preventing overheating and electrical breakdowns. Maintaining this precious fluid is like giving your transformer a regular checkup, ensuring it stays healthy and performs at its best. So, what's involved in this crucial process?

Transformer oil maintenance involves a series of tests, treatments, and sometimes even complete replacements. Regular testing analyzes the oil's dielectric strength, acidity, moisture content, and other crucial parameters. These tests reveal the oil's health and identify potential problems before they escalate. Think of it as a blood test for your transformer – a quick and easy way to catch issues early on.

Historically, transformer oil maintenance has evolved alongside transformer technology. Early transformers used less refined oils, but as voltage levels increased, so did the demand for higher quality, more stable insulating fluids. Today, transformer oil management is a sophisticated science, employing advanced filtration techniques and specialized equipment to keep the oil in peak condition. The importance of proper maintenance cannot be overstated; it directly impacts the reliability and lifespan of transformers, which are essential components of our power infrastructure.

One of the main challenges in transformer oil maintenance is preventing contamination. Moisture, oxygen, and other impurities can degrade the oil's performance, leading to reduced dielectric strength and increased risk of failure. Effective maintenance strategies focus on minimizing contamination through proper sealing, regular filtration, and periodic oil reclamation. This ensures the oil remains clean and effective, protecting the transformer from damage.

Regular oil sampling and analysis are vital for effective transformer maintenance. This helps track the oil's condition and identify potential issues like oxidation or contamination. Dissolved gas analysis (DGA) is another important tool, detecting gases produced by internal faults within the transformer.

Benefits of proper transformer oil maintenance include extended transformer life, reduced risk of failures and outages, and improved overall system reliability. For example, regular filtering can remove contaminants that accelerate oil degradation, preventing costly replacements.

A typical maintenance plan involves regular oil sampling, analysis, and filtration. If necessary, the oil can be reclaimed to restore its properties. A successful example would be a utility company implementing a proactive maintenance program, leading to a significant reduction in transformer failures.

Tips and Tricks: Always handle transformer oil with care, as it can be flammable. Ensure proper storage and disposal procedures are followed.

Advantages and Disadvantages of Different Maintenance Approaches

No table provided due to HTML format limitation.

Best Practices: 1. Regular sampling and testing. 2. Proper filtration techniques. 3. Effective oil reclamation. 4. Implementing a comprehensive maintenance schedule. 5. Maintaining detailed records.

Challenges and Solutions: Challenge: Oil contamination. Solution: Improved sealing and filtration. Challenge: Aging oil. Solution: Oil reclamation or replacement.

FAQs: What is transformer oil? Why is it important? How often should it be tested? What are the signs of degraded oil? What is oil reclamation? How is oil disposed of? What are the different types of transformer oil? What are the safety precautions for handling transformer oil?

In conclusion, maintaining transformer oil isn't just a routine task; it's a critical investment in the reliability and longevity of our power infrastructure. From ensuring efficient power distribution to preventing costly failures, the benefits of proper transformer oil management are undeniable. By understanding the crucial role of this incredible fluid and implementing a comprehensive maintenance plan, we can keep our electrical grid humming smoothly for years to come. Take action today and ensure your transformers are protected by the best oil maintenance practices. Remember, a little preventative care goes a long way in keeping the lights on and the power flowing.

Unmasking gray zone warfare the persisting shadow of conflict

Unlocking the potential of behr light gray paint

Behr premium plus satin interior paint a deep dive