Imagine a world without clear indicators of tank levels in industrial processes. Chaos, inefficiency, and potential hazards would likely reign. This is where the seemingly simple, yet crucial, IEC level switch symbol steps in. These symbols, standardized by the International Electrotechnical Commission (IEC), provide a universal language for representing level measurement and control in various industrial applications.

Understanding these symbols is fundamental for anyone involved in process automation, from engineers designing control systems to operators monitoring plant operations. The symbols act as a visual shorthand, quickly conveying critical information about the state of liquid or solid levels within tanks, vessels, or other containers. This clear communication helps prevent overflows, safeguards equipment, and ensures smooth process flow.

IEC level switch symbols are not just arbitrary markings. They are carefully designed graphical representations that adhere to specific standards. This standardization allows for consistent interpretation across different industries and geographical locations. Whether you're working with a level indicator in a chemical plant in Germany or a water treatment facility in Japan, the underlying meaning of the symbol remains the same.

The origin of these symbols stems from the need for a unified system of representation in electrical diagrams and documentation. The IEC, as a global organization dedicated to standardization in electrotechnology, took on the task of developing these symbols. This standardization effort has significantly contributed to improved safety and efficiency in industrial processes worldwide.

A key issue related to IEC level switch symbols is the potential for misinterpretation if not properly understood. This highlights the importance of proper training and education for personnel working with these systems. Incorrectly interpreting a symbol could lead to operational errors, potentially resulting in material waste, equipment damage, or even safety incidents.

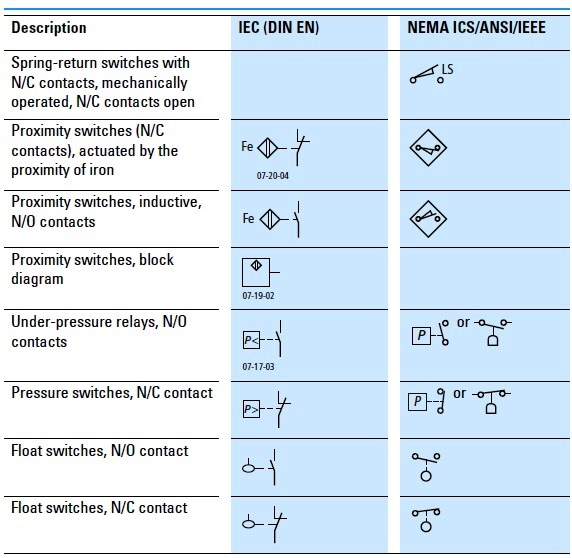

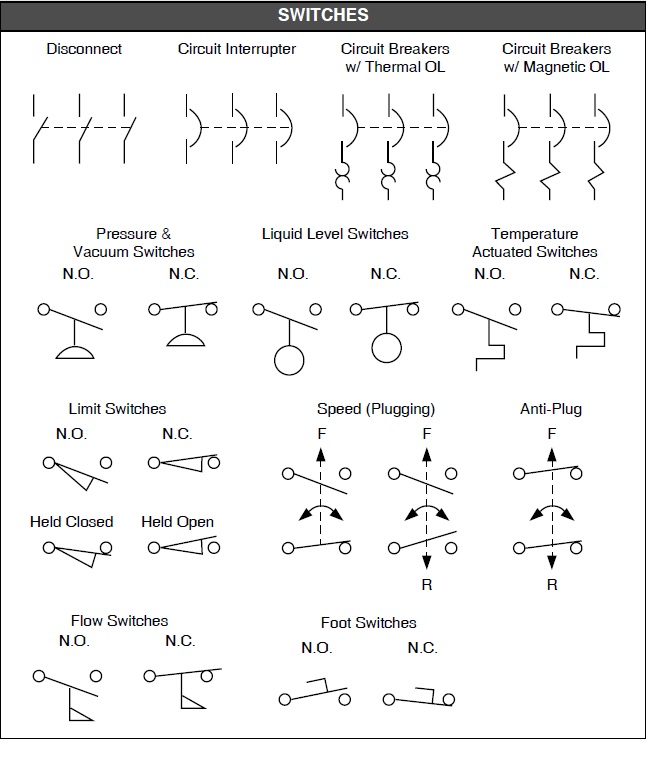

These symbols often represent different types of level switches, such as float switches, capacitive level switches, and ultrasonic level switches. Each type utilizes a distinct method for detecting levels, and the corresponding symbol reflects this functionality. For example, a float switch symbol might depict a float connected to a switch, visually representing the mechanism of operation.

Several benefits arise from using standardized IEC level switch symbols. First, they enhance communication and understanding among engineers, technicians, and operators. Second, they contribute to improved safety by providing clear and concise information about level conditions. Third, they support efficient troubleshooting and maintenance by enabling quick identification of components and their functions.

Ensuring accurate and reliable level measurement starts with selecting the appropriate symbol for the specific application. Consider the type of material being measured, the required level of accuracy, and the environmental conditions. Then, correctly integrate the chosen symbol into the overall process control system documentation.

Understanding and interpreting IEC symbols related to level control are vital for effective process automation and plant safety. These symbols represent a critical link between the physical process and the control system, enabling operators to monitor and manage levels accurately.

Advantages and Disadvantages of Standardized Level Switch Symbols

| Advantages | Disadvantages |

|---|---|

| Clear communication and understanding | Requires training and familiarity |

| Enhanced safety | Potential for misinterpretation if not properly understood |

| Efficient troubleshooting and maintenance |

Five best practices for implementing IEC level switch symbols include: 1) Ensuring proper training for all personnel involved; 2) Using clear and accurate documentation; 3) Regularly reviewing and updating symbols as needed; 4) Adhering to the latest IEC standards; 5) Integrating symbols seamlessly into the control system interface.

Frequently Asked Questions:

1. What is the purpose of IEC level switch symbols? - They provide a standardized way to represent level measurement and control.

2. Where can I find a comprehensive list of IEC level switch symbols? - The IEC website and relevant standards publications.

3. What are some common types of level switch symbols? - Float switch symbols, capacitive level switch symbols, ultrasonic level switch symbols.

4. Why is it important to use standardized symbols? - For clear communication, enhanced safety, and efficient maintenance.

5. What are the potential consequences of misinterpreting these symbols? - Operational errors, material waste, equipment damage, or safety incidents.

6. How can I learn more about IEC level switch symbols? - Through training courses, online resources, and industry publications.

7. Are there specific software tools for working with these symbols? - Yes, various CAD and automation software packages support IEC symbols.

8. How often are IEC standards updated? - Regularly, to reflect technological advancements and best practices.

Tips and tricks for working with IEC level switch symbols include using clear and concise labels, maintaining consistent symbol usage throughout the documentation, and referencing the latest IEC standards for accurate representation.

In conclusion, the IEC level switch symbol plays a vital role in modern industrial automation. These symbols provide a universal language for communicating critical information about liquid and solid levels, promoting safety, efficiency, and smooth operation. Understanding the meaning and application of these symbols is essential for anyone involved in process control and automation. By adhering to IEC standards and best practices, industries can ensure clear communication, minimize errors, and optimize their processes. Continuous learning and staying updated with the latest standards are crucial for maximizing the benefits of IEC level switch symbols. Embrace these symbols as a powerful tool for enhancing safety, efficiency, and overall performance in your industrial operations. Explore the resources available from the IEC and other industry organizations to deepen your understanding and stay ahead in the ever-evolving world of automation.

Unleash the subtle power of pebble grey ppg paint

Rock that silver fox mastering the ash grey hair look for men

Finding your true north decoding the feng shui house direction dilemma