Ever wondered about that satisfying click of a properly tightened bolt? It's more than just a sound; it's the assurance of a secure and stable connection. When working with fasteners measured in inches, feet, and pounds, you're dealing with the imperial system, and understanding the correct torque values is essential. This brings us to the crucial world of imperial bolt torque specifications.

Imagine building a bookshelf, assembling a bicycle, or even working on a car engine. Each bolt plays a vital role, and over-tightening or under-tightening can lead to disastrous results. An over-tightened bolt can strip threads or even fracture, while an under-tightened bolt can loosen over time, compromising the entire structure. That's where an imperial bolt torque specification chart comes in handy.

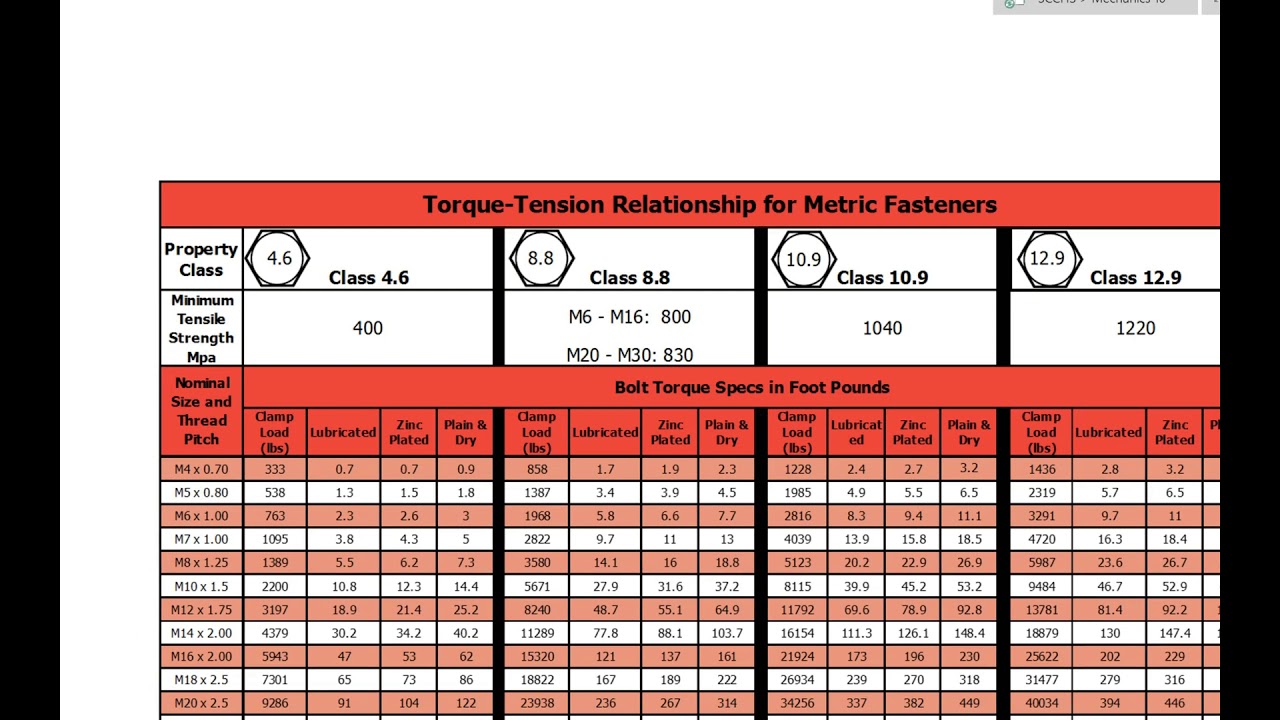

Essentially, a bolt torque specification chart provides recommended tightening values for different bolt sizes and grades within the imperial system. These values are carefully calculated based on factors such as the bolt's material, diameter, and thread pitch. Using the correct torque ensures that the fastener is tightened enough to hold securely but not so tight that it causes damage. Think of it like Goldilocks finding the perfect porridge – not too hot, not too cold, but just right.

The history of standardized torque specifications is intertwined with the development of industrial manufacturing. As machinery became more complex, the need for precise and consistent fastener tightening became paramount. Over time, engineers and scientists developed standardized charts and tables to guide assembly processes, ensuring reliability and safety. While the exact origins are difficult to pinpoint, the importance of these specifications is undeniable.

One of the main issues related to imperial bolt torque values is the potential for confusion. Different manufacturers might have slightly different recommendations, and various factors like lubrication can influence the final torque. It's crucial to consult the appropriate resources and consider the specific application to determine the correct torque value. Imagine using a recipe but not adjusting for altitude – you might end up with a very different result than intended.

A simple example: a 1/4-inch diameter steel bolt might have a recommended torque of 7 foot-pounds. This means you would apply 7 pounds of force to a wrench that is 1 foot long. A torque wrench, a specialized tool that clicks or displays a reading when the desired torque is reached, is essential for accurate tightening.

One benefit of using an imperial bolt torque chart is preventing damage to the fastener or the materials being joined. Another benefit is achieving consistent clamping force, which ensures that the joint remains secure under various loads and conditions. Finally, using the correct torque can extend the lifespan of the bolted joint, reducing the need for frequent maintenance or repairs.

An effective action plan for using imperial bolt torque values involves identifying the correct bolt size and grade, consulting the appropriate chart or table, selecting the correct torque wrench, and applying the specified torque in a slow and controlled manner.

Advantages and Disadvantages of Imperial Bolt Torque Charts

| Advantages | Disadvantages |

|---|---|

| Provides standardized torque values | Can be confusing with varying manufacturer recommendations |

| Helps prevent damage from over-tightening or under-tightening | Requires specific tools like a torque wrench |

| Ensures consistent clamping force | Lubrication and other factors can affect torque values |

Best Practice: Always consult the manufacturer's specifications for your specific application.

Best Practice: Use a calibrated torque wrench for accurate tightening.

Best Practice: Clean and lubricate threads before tightening.

Best Practice: Tighten bolts in a sequence to ensure even distribution of clamping force.

Best Practice: Regularly inspect bolted joints for looseness.

FAQ: What is torque? Torque is a twisting force that tends to cause rotation.

FAQ: What is a foot-pound? A foot-pound is a unit of torque in the imperial system.

FAQ: What is a torque wrench? A torque wrench is a tool designed to apply a specific amount of torque to a fastener.

FAQ: How do I choose the right torque wrench? Select a torque wrench that covers the range of torque values you'll be using.

FAQ: What happens if I over-tighten a bolt? Over-tightening can strip threads or fracture the bolt.

FAQ: What happens if I under-tighten a bolt? Under-tightening can cause the joint to loosen over time.

FAQ: Where can I find imperial bolt torque charts? Many manufacturers provide torque charts in their product documentation or online.

FAQ: What is the importance of proper bolt tightening? Proper bolt tightening ensures the safety, reliability, and longevity of assembled components.

Tip: Keep your torque wrench calibrated for accurate readings.

Tip: Use a torque chart specific to the materials you are working with.

In conclusion, understanding and applying correct imperial bolt torque specifications is paramount for any project involving fasteners. From assembling furniture to building complex machinery, the correct torque ensures safety, reliability, and longevity. By utilizing a reliable imperial bolt torque chart, employing appropriate tools like a torque wrench, and following best practices, you can achieve optimal fastener performance and avoid costly mistakes. Don't underestimate the power of that satisfying click – it's the sound of a job well done. Remember to always consult the appropriate resources for your specific application, and don't hesitate to seek expert advice when needed. The world of fasteners may seem small, but its impact on our everyday lives is immense. So, next time you pick up a wrench, remember the importance of those seemingly simple numbers on an imperial bolt torque chart – they hold the key to a secure and stable connection.

Decoding the paris 2024 olympics agenda

Navigating dental coverage your guide to waterloo university dental insurance

Navigating the dynamics of childhood friend complex chapter 26